is our Passion

Contact Us Today for a Quote!

866-787-4360

| Safety is our Passion |

|

Contact Us Today for a Quote! 866-787-4360 |

|

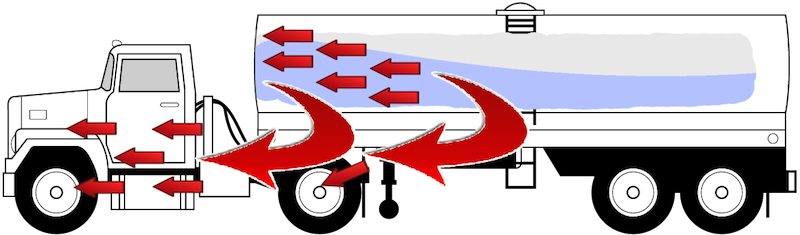

Surge Busters® work together as a surge suppression system. It is important to have the required number installed in a given tank because they compliment each other in the surge reduction process. Let’s look at an example of a truck that is coming to a stop and creating a significant amount of liquid surge in the tank as the trucks brakes are applied. |

The force generated by the liquid in the tank is equal to the force that must be absorbed by the rest of the truck.

|

In the typical truck with no baffles, as the truck comes to a stop, the liquid keeps moving forward, piling up and pushing against the front wall of the tank. Then the liquid rebounds off the front of the tank and travels all the way to the rear tank wall, where it rebounds back to the front. This is repeated over and over again until the energy is gone. Except in daily stop and go driving, it never really stops. The entire process keeps re-starting. This energy is then transferred through the rest of the truck's components, wearing on the brakes, shocks, drive train, engine, frame, tires -- everything! This wear and tear is very hard on components and increases maintenance costs over a period of time. Aside from the wear to the tractor and trailer, the weight in the tank shifts dramatically, increasing the risk that the driver and the others on the road could have an accident, or even worse, a rollover, particularity on bends, sharp turns, wet or icy roads, and emergency stops, or accident avoidance maneuvers. |

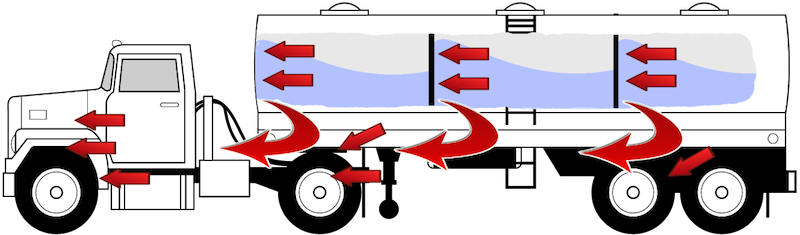

The force generated in the tank is still equal to the force that must be absorbed by the rest of the truck even though the tank is subdivided.

|

In a truck with traditional baffles installed in the tank, less force is generated by moving liquid because it does not travel as far since it is divided up between the baffles. This energy is still transferred from each baffle to the rest of the rig but is spread out more evenly to the entire truck. This energy is easier to handle when evenly distributed but still places the equipment under significant stress. Although better than not having any baffles, this scenario is still unstable and does nothing to decrease the potential for a rollover accident. To repeat, fixed baffles in a tank, do nothing to reduce the likelihood of a rollover accident. |

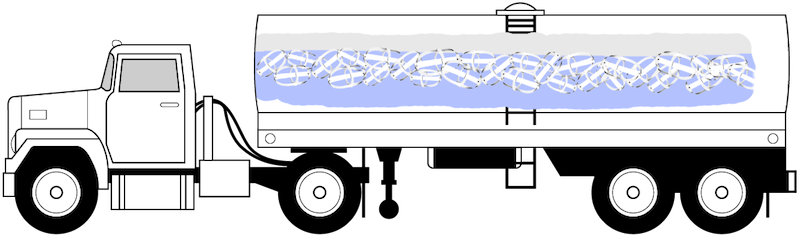

Unlike other surge supression products, Surge Busters float in the top 1/3 of the tank.

|

Surge Busters work to dissipate the liquid energy inside the tank. When our Surge Busters® are installed in a tanker, they float in the top 1/3 of the liquid and work in concert with each other to generate a Surge Elimination System. It is important to have the required number for them to work properly based on tank size and the liquid’s weight per gallon. |

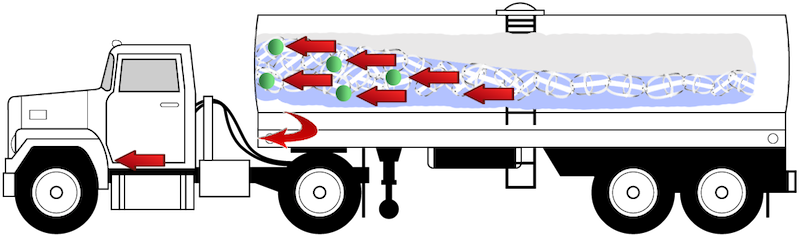

The force generated in the tank is mostly eliminated, with only a small percentage (approximately 4%) being transferred to the truck.

|

As the truck slows down and the liquid begins to slosh and move toward the front of the tank, the Surge Busters® suspended in the liquid move as well and congregate at the focal point of the surge energy. This baffle system begins to bend, flex and then recoil against the surging liquid, dissipating the energy in the process. These individual pieces work together as a large “shock absorber” for the moving liquid. This process happens very quickly creating 1000’s of multi-directional eddies, disrupting and quelling the surge wave. Once the truck comes to a stop, the opposite movement of liquid toward the back of the truck is similarly reduced and comes to rest much faster than with traditional fixed baffles. |

|

Copyright © 2025 Liquid Surge Control, LLC. All rights reserved. |